General precautions

-

The hot

compound in chillis is capsaisin.

Avoid contact with mucous membranes (e.g. eyes and nose);

Wear gloves when needing to be in skin contact.

-

Sliced or

blended chillis will release irritating fumes/aerosols.

Take precautions not to inhale these fumes or risk eye, nose

and lung irritation (coughing is the usual response).

-

You are making

a food product.

Exercise maximum hygiene/sanitation in all your procedures.

Lacto-fermentation

-

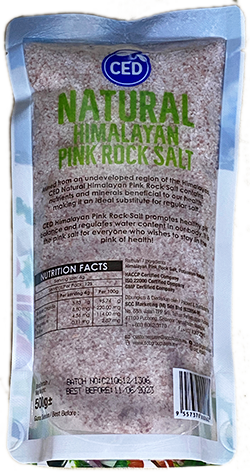

Make a brine solution which is 6% (w/v) in strength.

Note: The salt concentration chosen is critical because if

the salinity is not high enough, pathogenic or food-fouling

microorganims may flourish and make the brew dangerous to

consume.

6% is higher than what is usually used by others but I chose

to err on the side of safety. The disadvantage of too high a

salinity is that the fermentation may proceed very slowly.

Bird's eye chillis

The choice of chilli to ferment is up to you and

where you wish to be on the Scoville Heat Unit scale

-

Slice bird's

eye chillis (I used 250 g) into into halves to expose the

ribs and seeds. Then further chop up the batch into smaller

pieces.

Some folk mash/grind up the chillis at this stage but my

take on this is that if the chillis are broken up too

finely, the juices within (containing the desired capsaicin)

will be contained in the saline. Not all this saline will

end up in the hot sauce later. It is better to mash up the

chillis after fermentation in order to conserve the hot

compounds within.

-

Smash and

slice 6 cloves of fresh garlic.

-

Place both the

chillis and garlic into a suitable container which can be

sealed tightly to keep out air. I used a small Mason

jar.

-

Now add

sufficient of your prepared brine to cover the chillis and

garlic. It is not necessary to weigh the chillis/garlic down

into the brine if you shake the ferment daily until the

produce no longer tends to float.

Sliced bird's eye chillis and garlic in brine at Day 0

-

Allow the

ferment to brew for at least 14 days.

Shake the contents daily to dislodge entrapped gas, and

"burp" the container to release the ferment gas to atmosphere.

-

You may wish

to ferment for longer than 14 days to obtain more flavour.

The ferment at Day 14

-

Strain.

At the end of the fermenting period, drain the chillis into

a fine sieve and collect the solids. Retain the briny fluid

as this will contain the lactobacillus for subsequent

fermentations, and you will need some of the liquid for

preparing the next step.

-

Blend.

Add some of the fermented brine to the chilli solids and

blend until a very smooth mixture results. The thickness or

runniness of this mixture is up to your preference.

Tabasco sauce is particularly liquid.

-

Acidify.

You can add a vinegar of your choice to the blend to

give your hot sauce some tartness but also increase its

potential for longer shelf-life (acidity deters microbial

growth). You can add one part vinegar to 2 parts chilli

blend (for ease of procedure, do this by weight on a

balance).

-

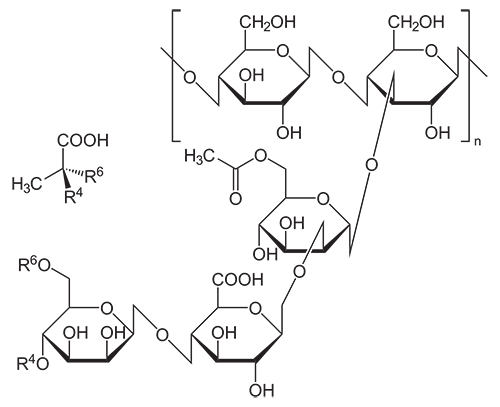

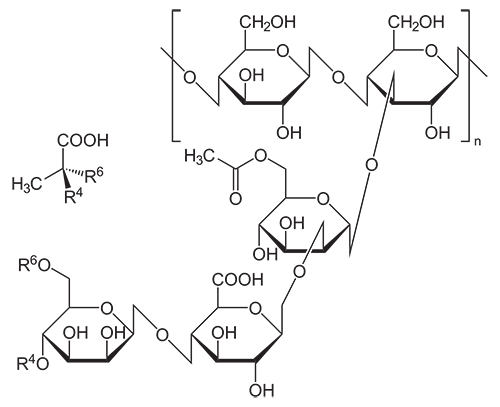

Xanthan.

At some stage of the blending process, you may wish to add

xanthan gum to produce a mixture with a smooth viscosity

which does not separate over time into liquid and solids.

One quarter teaspoon to 200 mL of liquid is a good start.

Add more if you want a higher viscosity. Note that you

should only add xanthan to a mixture that is being

vigorously agitated e.g. add the powder as you are blending.

If you add it to still liquid you are likely to end up with

clumps which are hard to disperse.

Molecular structure of xanthan

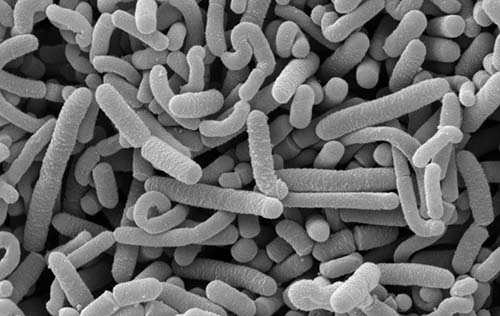

Xanthan gum is a

polysaccharide made by the bacterium Xanthomonas campestris

in fermentation. It is a highly versatile polymer with

interesting properties which make it very useful for food

applications (look at the labelling of foods which are a paste or

liquid - you will often see xanthan as an additive [given the

code E415]). Xanthan is used as a thickener which holds solids

in suspension in liquids so that they fall out of suspension

only very slowly. It is stable against acid and alkali

conditions, and is thermostable. It is thixotropic which means

that its viscosity decreases when a shear force is applied to it

- this is the property of sauces such as tomato which only comes

out of their bottles easily after you give the bottle a good

shake.

-

Bottling.

Decant the blended mixture into suitably sized bottles

with caps.

Bottled (120 mL)

and ready for pasteurization.

This is the quantity (2 and 1/2 bottles) arising

from 250 g of chillis at the start.

Pasteurization

This step is done

to stop the fermentation (the microorganisms are rendered

unviable) and to assure a sufficient shelf-life to the prepared

sauce. If the fermentation is not stopped (some people do like

an unpasteurized product), gases could be produced while in

storage and content may spill over upon the bottles being opened

(this happens with cincalok).

-

Place the

bottles of sauce in a saucepan filled with sufficient water

to immerse the bottles up to the level of the sauces held

within.

-

Heat the water

in the saucepan until boiling and hold it there until the

sauces in the bottles reach at least 80 degrees centigrade.

-

Hold 80

degrees centigrade for at least 30 minutes to complete

sufficient pasteurization.

Note that while pasteurization removes sufficient viable

cells of most food spoilage and poisoning microorganisms, it

is not the same as sterilization. Pasteurized products

cannot be stored indefinitely and thus, when you are

consuming your pasteurized sauce, store the remainder in a

refrigerator to extend its shelf-life.

You may like to

decant portions for meals and further adjust the taste of the

sauce prior to serving. You can cut/blend the sauce with

vinegar,

calamansi juice, add sugar

or fish sauce. As you please.

n.b. Ask an Aussie

what Brown-eye means |