|

A description of the

first (koji)

stage is found

here

The second (moromi)

stage

Saline fermentation

I chose the brine method (there is also a relatively

dry salt method).

Method

Make up a brine

solution which is at least 15 but not more than 20% common table

salt (I used 18%) on a weight to volume basis. I made up my

brine in the following way to immerse the 1.5 kg (starting

weight) of koji (fermented soya beans + wheat berries)

which was prepared in the first stage:

-

1200 mL clean

fresh water

-

108 g Himalaya

Pink Rock Salt

-

108 g

Australian Sea Salt

You can use any

salt of your fancy (you might discern a subtle difference later,

or your choice may be the mark of your special brew).

Note: Salt is added in the moromi stage in order to favor

halophilic microorganisms which can thrive in the high osmolarity

of the saline condition created. Through the biochemical metabolism of these saline microorganisms, the fermentation

substrates in which were produced in the koji stage are converted to

the complex compounds typically found in soya sauce which

contribute to its flavor profile. Of these, glutamic acid should sound familiar because it is the very

acid which is used to make monosodium glutamate, commonly known as

"MSG". The latter occurs in soya sauce because of the

presence of both sodium ions (from the added salt) and glutamic acid (from the

microbial metabolism of breakdown products from soya and wheat

proteins). If the salt is in

insufficient concentration, undesirable (off-flavor and/or

possibly pathogenic varieties) microorganisms may predominate

instead of the moromi microorganisms. On the other hand,

if the salt concentration is too high, even growth of the

moromi microorganisms may be deterred or slowed down,

leading to very long brew times being required.

Brewing

-

Place the

prepared koji into a suitable sized container. I

used two 1.8 L Mason jars.

-

Add sufficient

brine to mix and immerse the koji well.

-

Cover the jar

with a securable cloth top, or close down the lid if Mason

jars are used.

Day 0 of the moromi stage

-

Stash the

fermenting brew in a warm corner in your kitchen.

Warmth helps the fermentation to

proceed at a good pace.

-

Monitor the

brew daily initially.

Stir the contents to distribute the mix as required.

-

After some

weeks, it may only be necessary to mix the brew

hebdomadally.

At Month 1 of the

moromi

stage

At Month 2 of the

moromi

stage

At Month 3 of the

moromi

stage

The koji brew is visibly more liquified now and has

settled down in volume

At Month 4 of the

moromi

stage

At Month 5 of the

moromi

stage

Liquidization is apparent now and dark brown

free liquid (soya sauce) can be seen.

At Month 6 of the

moromi stage

Liquidization is

not only apparent but can be "heard" when

the bottles are

shaken. The volume of the brew is a lot

less than at the beginning.

At Month 7 of the

moromi stage

The brew can be

easily moved inside the bottles now

and brown fluid (the sauce) is visible. Volume of the

brew has shrunk significantly.

-

Allow the brew

to ferment for around 6 months to a year.

In my case, I intend to let the brew go for 12 months.

-

You can

perform a taste test after 3 months and track how the brew

is proceeding by both taste and look.

The brew should turn darker with time and the beans/meal

should slowly disintegrate.

12 months later

(Nov 2022) . . . .

Filtration

-

When you are

satisfied with the brew in terms of taste and color, you can

stop the brew and filter.

-

For

filtration, use cotton gauze or something similarly

appropriate (fine sieve perhaps), to strain the brew to

remove particulates and harvest clear, dark soya sauce. You

will need to squeeze the gauze at the end of the process to

extract the residual entrained liquid.

The 12-month fermented moromi after extraction from the

the brew vessels and placed on cotton gauze ready for

filtration.

-

Filtration

proved to be a lot more difficult than anticipated as it

should be obvious (not to me initially) that to extract

liquid from a paste will always be difficult. Due to a lack

of a press (which is used in soy sauce making), I only

managed to filter/squeeze out a minimal amount of soy sauce.

Filtration was not to a high degree and so the sauce

remained cloudy with particulates.

Pasteurization

-

When you have

finished harvesting all the liquid that you can extract,

place it in a sauce pan, heat it to at least 80

degrees centigrade and hold this temperature for at least 30

minutes.

This pasteurization serves to stabilize the sauce

against further microbial growth/action to benefit longer

shelf-life, and add a measure of food safety (common

pathogenic microorganisms are destroyed). Heat treatment also develops the flavor profile of the

sauce.

Note: At this stage you may wish to make blended soya sauce

by making flavor additions e.g. you could add cleaned dried mushrooms to the

sauce during pasteurization. This will result in mushroom soya sauce.

Those who

believe in monosodium glutamate as a flavor enhancer can

fortify the umami quality of your sauce by

adding monosodium glutamate (MSG). Sugar can also be added

to make a sweet version of the sauce (although depending on

concentration, this may shorten shelf-life).

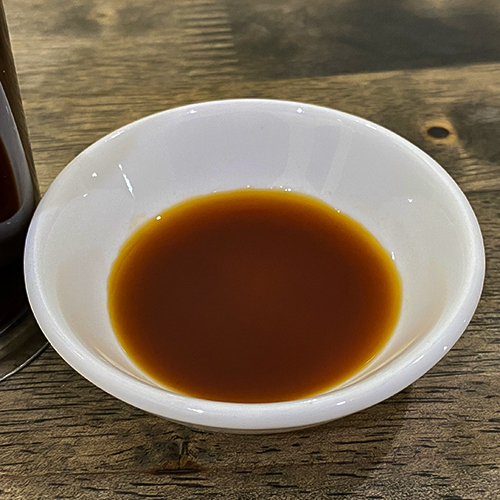

Crude-filtered freshly brewed soy sauce being pasteurized for at

least 30 minutes in boiling water

-

Decant the

sauce into clean containers.

-

For longer

term storage, keep the sauce in a refrigerator until it is

to be used.

-

I left the

saltiness of the sauce as brewed in order that the salinity

will preserve it better. The sauce can be adjusted for

saltiness just before use by addition of water.

|