Clem's

sake

|

|

Sake falls

within that group of alcoholic wines brewed using rice as the

carbohydrate source. It is Japanese in origin with

the key features of

utilizing (i) particular rice varieties; (ii) only highly

polished rice (unlike other rice wines from other cultures; the

level of polishing desired removes between 40 to 60 % of the

outer kernel) as this minimizes the flavours imparted by any retention of bran and non-starch

components of raw rice; (iii) a hydrolysation stage (kome

koji) where sugars are released by the breakdown of rice

starch by the enzymatic action via a fungus.

The rice variety used is

Oryza sativa subsp. japonica. This is a short-grain

variety with a higher amylopectin content than long-grain rice

(the other component of rice starch is amylose) which gives rise

to a sticky characteristic when cooked.

|

|

The short-grain Japonica rice

which I used (labelled as bento rice)

|

|

|

|

Starches are polymers of

glucose units. They are only

fermentable after they are saccharified to release fermentable

sugars. Kome koji fungi are used for starch

saccharification because they produce amylases such as

alpha-amylase and glucoamylase. Amylopectin is more difficult to hydrolyze by kome-koji fungi because of its alpha 1-6

linkages (between glucose molecules in starch) are only susceptible to glucoamylase. Hydrolysis by glucoamylase (to release monomers of

glucose) is slower than via alpha-amylase (acting on alpha 1,4

linkages in amylose to release short chain amylose or dextrins

or oligosaccharides) and because glucoamylase is an exo-amylase

(acting only on chain ends) whereas alpha-amylase is an endo-amylase

(acting from within polymer chains).

Koji kin is the

fungal agent used for hydrolysis. It is typically Aspergillus

oryzae.

|

|

A conidiophore of Aspergillus

oryzae

|

|

MATERIALS AND

METHOD

GENERAL PRECAUTION

You are

making a food product which is consumed without cooking.

Exercise maximum hygiene/sanitation in all your procedures and

disinfect equipment prior to usage.

Making kome koji (saccharification by a live

fungal agent to produce hydrolysed rice starch)

Starches

are stored in crystalline granules. These need to be "hydrated"

in a step called "gelatinization" where polymeric starch is

brought into solution and thus becomes amenable to further

chemical and physical transformation e.g. via enzymatic

hydrolysis. Rice starches gelatinize in the temperature range 68

- 78 degrees centigrade.

-

Take

240 g of polished short-grain rice and wash thoroughly until

the water runs clear.

This will remove any remnants from outer rice layers and

also prevent the steamed rice granules from tending to stick

together.

240 g of resulting kome koji is the quantity which

when added to 1 kg of cooked rice and 1 L of water will be

the fermentation mash (see below).

-

Steam the rice until the grains are plump and soft.

This is the arrangement which I used:

|

|

A large sieve, a large pot and a lid to cover.

This was around halfway through a 2 h steaming process

|

-

Spread the steamed rice onto a sterilized tray and let

the steamed rice cool down (to at least 30 degrees

centigrade).

-

For my source of the fungus, I used commercially available

kome koji (what is being made in this step viz.

steamed rice upon which Apergillus oryzae is

cultured).

This is the kome koji which I bought online:

|

|

Koji kin available

online

|

-

Finely grind 5 - 10 g of the kome Koji .

-

Mix

the ground kome koji well into the rice, cover (not airtight) and leave in a

warm corner of a room for the fungus to grow throughout

the rice. In growing on the rice, hydrolytic amylolytic

enzymes released will break down starch into fermentable sugars for

the next stage of the process.

Check the inoculated rice regularly while taking care not to

introduce contaminants into the mix; mix the rice with a

sterilized utensil at these points to ensure even

development of the fungus.

-

The

process may be stopped after some 30 - 48 h if the culture

progressed optimally.

You now have kome koji for the

alcoholic fermentation stage.

-

The property of

kome koji which is desired for the sake process is its content of amylolytic ezymes such as

alpha-amylase and glucoamylase which are required to

saccharify rice substrate which will be added in the

fermentation stage. These enzymes accumulate in the kome

koji as the koji kin fungus grows throughout the rice

during the preparation of kome koji. Without

the agency of these enzymes, the starches in the added rice

substrate will not be fermentable by the yeast cells added

together with the rice.

|

|

kome koji

ready to use after a two-day incubation

|

|

Preparing the yeast

inoculum

Some

36 h before needing to use it, start

making the yeast inoculum:

-

Take

10 g of ground kome koji and add 100 mL of sterilized

water at room temperature to a sterilized container with a

lid.

-

Add

a few grams of dried yeast and set aside in a warm corner of

a room for the yeast to multiply.

I used a wine yeast strain which was bought online but you

can experiment with various types including sake

strains if you can find them (sake strains generally

have higher alcohol tolerance).

-

The

inoculum will be ready to use after 24 h.

|

|

The yeast

Saccharomyces cervesiae used in ethanolic fermentations

|

|

The alcoholic fermentation

(sake stage)

It is now

time to combine the kome koji with more rice substrate.

-

Cook

400 g of short-grain rice until soft (thus ensuring that all

the rice starch granules in the kernels are gelatinized).

Allow it to cool to at least 30 degree centigrade.

-

In a

suitably-sized container with a tight lid, combine:

-

the

cooked rice;

-

135

g of kome koji previously prepared;

-

1.5 L

of boiled water allowed to cool to at least 30 degrees

centigrade;

-

100

mL of the yeast inoculum previously prepared.

-

Stir

well with a sterilized utensil, close the container and set

aside in a cool room for 10 to 14 days.

Through the days, the saccharolytic enzymes in kome koji

will cleave polymeric starch in the cooked rice to produce

fermentable sugars and the yeast in the inoculum will in

turn grow and convert those sugars into ethanol.

|

|

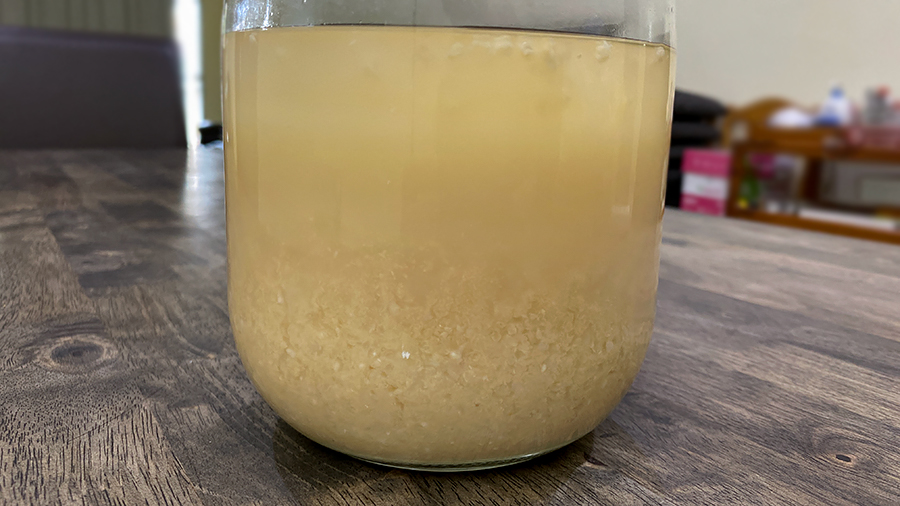

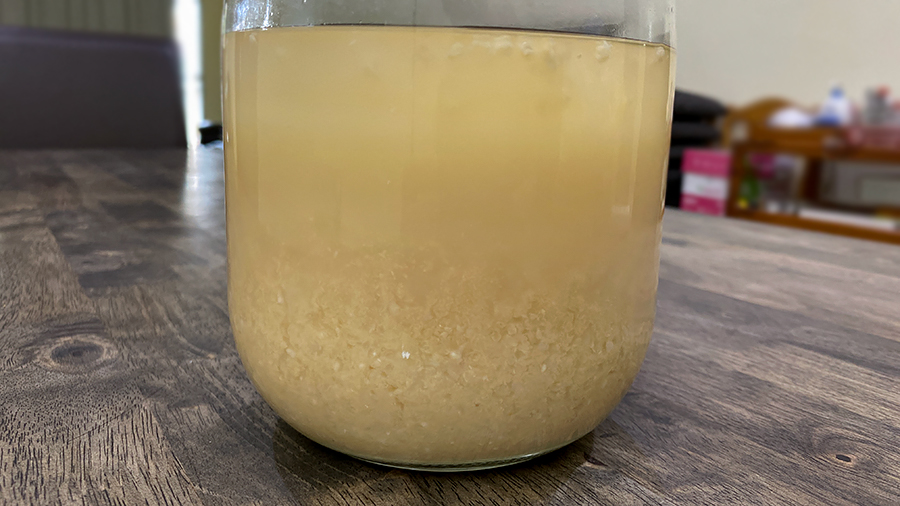

The brew at the beginning of Day 2

|

-

Check

the brew each day and allow gas build up to vent if you do

not have a water trap on the lid of the brew container

("burp" the vessel).

You should notice bubbling (CO2 evolution) from the first day.

-

When

active bubbling has ceased, your brew is ready.

Fermentation will typically cease when the substrate runs

out or when the ethanol concentration has gone higher than

what the yeast cells can tolerate. The two are related since

high alcohol content can only be reached if the starch has

been well cleaved and there was a sufficient amount of the

latter supplied at the start of the brew. In home

fermentations such as described here, starch substrate is

probably in excess. Given that sufficient fermentable sugars

are released during the brew, fermentation probably ends due

to the yeast's alcohol tolerance being exceeded.

|

|

The brew at the

end of Day 7

Active bubbling has stopped; quantity of large particulates have

reduced; clearer brew at the top

|

|

Clarification

At the

end of fermentation, there will

be a lot of rice and yeast matter in your brew and so you may

wish to have a more clarified product. You can:

-

Pour

the fermented brew mash through a fine sieve to remove coarse

matter.

-

Allow

the larger particles in the sieved brew to settle by placing

it in a refrigerator over a few days. This is called

"cold-crashing". Decant the clearer brew at the top and it

will be ready for drinking.

-

You

choose to further clarify the product by passing it through

a cloth or finer filter matrix.

-

Sake

can be drunk fresh in cloudy or clear form according to preference as is the

choice of it being cold or warmed up.

-

For

storage, the fresh sake should be pasteurized by

holding it at 65 degrees centigrade for at least 30 minutes.

|

|

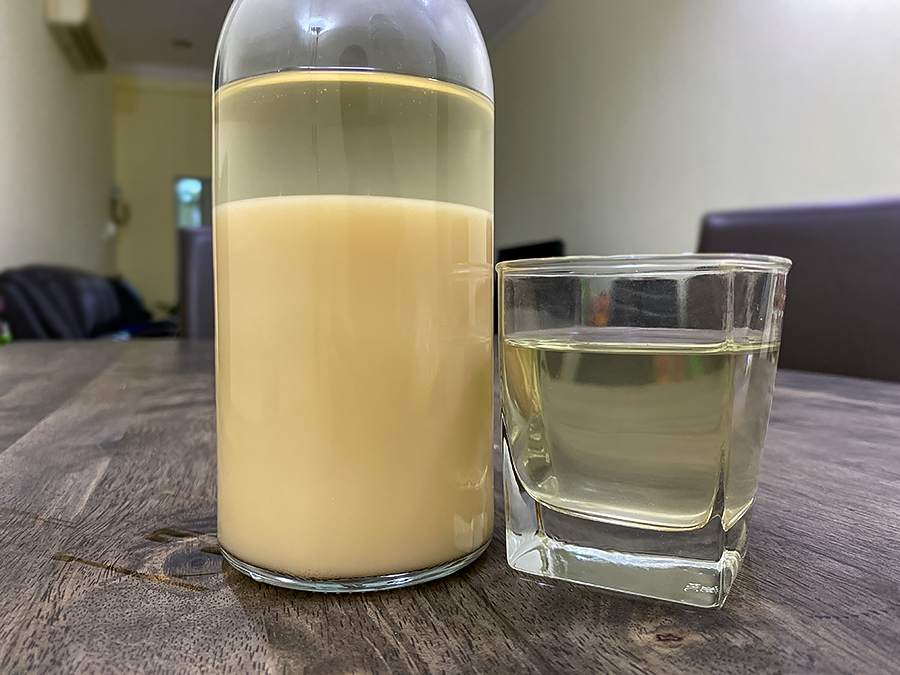

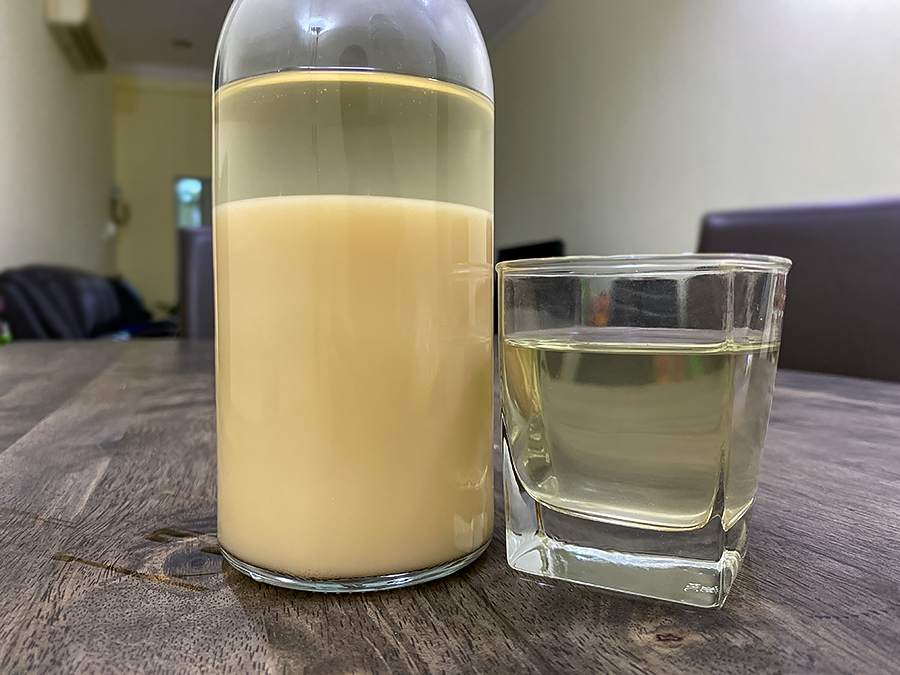

Left: Day 7 brew

after sieve-filtration and cold-crashing overnight in the refrigerator

Right: Cold, clear sake decanted from the top of the

cold-crashed brew on the left.

ENJOY YOUR

EFFORTS! |